Machinery Spotlight: Unveiling the Power Behind Construction Projects

In the fast-paced world of construction, the heartbeat of progress is powered by advanced machinery. This article explores the evolution of construction machinery, from humble beginnings to the cutting-edge technology that shapes modern construction projects. We trace the journey from Hungarian Kubikos and early agricultural machines to today’s sophisticated diesel engines and hydraulic systems.

A Glimpse into History From Labourer Diggers to Kubikos Workers

The term “kubikos” refers to a migrant labor force that moved vast amounts of the earth for construction projects, roads, and railroads, as well as flood control and river management using basic hand tools.

The name “cubic meter,” which relates to the fact that land workers were paid based on the quantity of land that was excavated and moved, is derived from the German word “Kubikmeter.”

From the second part of the 19th century to the Second World War, Hungary was known for its cubic work.

Early Agricultural Machines

Explore the transition from manual labor to the era of early agricultural machines, a pivotal point that revolutionized construction processes and increased efficiency.

In the 19th century, the United States and Britain saw the emergence of the agricultural machinery industries. The sickle and the plough were the standard farming implements up until that point. The blacksmiths in the village typically doubled as farriers in addition to forging iron agricultural tools. Some of the earliest producers of agricultural machinery sprang from these blacksmith shops in the early 19th century, including John Deere, who began manufacturing ploughs in series in the 1840s.

The advent of transportable steam-powered plowing engines occurred in the middle of the 19th century. They were utilized in pairs, positioned on opposite sides of a field, and a wire cable was used to pull a plow back and forth between them. Pumps, mills, and threshing equipment were also powered by these transportable engines. Certain farm machinery manufacturers, such as Ransomes, Sims, and Jefferies, who began as brass and iron founders producing casting ploughshares in the late 18th century, were the ones who manufactured the portable steam engines.

Revolutionary Era of Machinery

At the beginning of the 20th century, the following generation of tractors relied mostly on internal combustion engines, initially powered by gasoline and then by diesel. Early businesses made the move into the tractor industry. One such company was John Deere, which in 1918 acquired the Waterloo Gasoline Engine Company, makers of the well-known Waterloo Boy tractor. In tractors and other farm equipment, new technology including hydrologics and rubber ties was introduced in the 1930s. The development of the self-propelled, combined harvester and thresher, or combine harvester (often abbreviated as “combine”) was also aided by the diesel engines. These combine chopped, threshed, and segregated grain while continually traveling across the field, as opposed to cutting the grain stalks and transferring them to a stationary threshing machine.

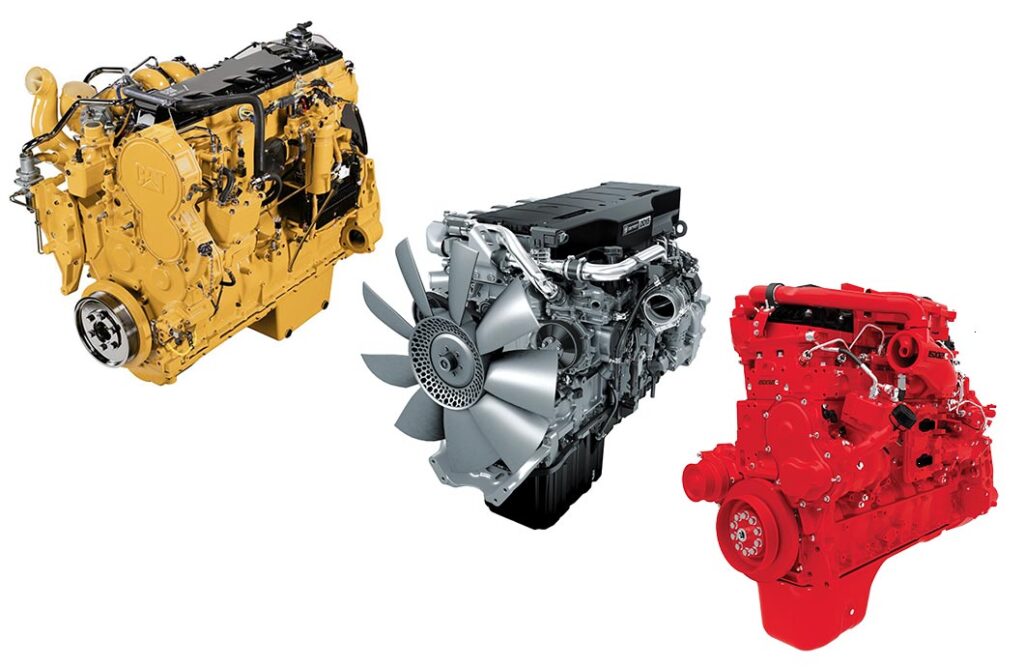

The Rise of Diesel Engines

Diesel engines have had a profound impact on the construction industry, revolutionizing the way heavy machinery operates and contributing to increased efficiency, power, and versatility. Here are several ways in which diesel engines affect the construction industry:

Increased Power and Torque

Diesel engines are renowned for their high torque output, providing substantial power at lower RPMs (Revolutions Per Minute) compared to gasoline engines. This characteristic is crucial for heavy construction equipment, allowing them to handle demanding tasks, such as excavation, lifting, and hauling, with greater efficiency.

Fuel Efficiency

Diesel engines generally offer better fuel efficiency than their gasoline counterparts. Construction projects often involve long hours of continuous operation, and the fuel efficiency of diesel engines helps reduce overall operational costs, making them a preferred choice for construction machinery.

Durability and Longevity

The robust construction of diesel engines makes them well-suited for the harsh conditions of construction sites. Their sturdiness and ability to withstand heavy loads contribute to increased durability and longevity, reducing maintenance costs and equipment downtime.

Versatility Across Applications

Diesel engines power a wide range of construction equipment, including excavators, bulldozers, cranes, and generators. Their adaptability and versatility make them suitable for various applications, allowing construction companies to use a standardized engine platform across different types of machinery.

Torque at Low RPMs

Construction equipment often requires high torque at low speeds, especially when dealing with heavy loads. Diesel engines excel in providing ample torque at low RPMs, making them ideal for the demanding tasks of construction machinery.

Suitability for Remote Locations

Construction projects are not always situated in urban areas with easy access to fuel stations. Diesel’s energy density and the availability of the fuel in remote locations make it a practical choice for construction equipment operating in diverse environments.

Economic Considerations

Diesel fuel tends to have a higher energy content than gasoline, contributing to the overall efficiency of diesel engines. While the initial cost of diesel engines may be higher, the long-term economic benefits, including lower fuel consumption, often make them a cost-effective choice for construction companies.

Environmental Impact

While diesel engines are known for their efficiency and power, concerns have been raised about their environmental impact due to emissions. However, advancements in technology have led to the development of cleaner-burning diesel engines, meeting stringent emission standards and reducing their environmental footprint.

Hydraulic Systems: Revolutionizing Precision

The use of hydraulic systems has transformed the way machinery operates, enhancing precision, control, and overall productivity. Here are several ways in which hydraulic engines affect the construction industry:

Precise Control and Responsiveness

Hydraulic systems offer precise control over the movement of construction equipment. The ability to control speed, direction, and force with accuracy allows operators to perform intricate tasks, such as digging, lifting, and positioning, with enhanced responsiveness.

Increased Power Density

Hydraulic engines provide a high power-to-weight ratio, enabling construction machinery to deliver significant force and performance without excessive bulk. This characteristic is particularly advantageous for heavy equipment where space and weight considerations are critical.

Versatility in Applications

Hydraulic systems are versatile and can be adapted for various construction applications. They are commonly used in excavators, cranes, bulldozers, and other heavy machinery, showcasing their adaptability across a wide range of construction tasks.

Efficient Energy Transmission

Hydraulic systems efficiently transmit energy, allowing for the transfer of power over long distances without a significant loss. This efficiency is vital in construction machinery, where the power generated by the engine needs to be transmitted to different parts of the equipment.

Safety Features

Hydraulic systems incorporate safety features such as pressure-relief valves, which protect equipment and operators from excessive pressure. This contributes to a safer working environment, reducing the risk of damage to machinery and potential accidents.

Compact Design

Hydraulic components can be designed to be compact and fit into tight spaces. This design flexibility is advantageous in the construction industry where machinery often operates in confined areas or undergoes complex movements.

Ease of Maintenance

Hydraulic systems are known for their durability and ease of maintenance. Regular maintenance is crucial for construction machinery, and the simplicity of hydraulic systems contributes to reduced downtime and overall lower maintenance costs.

Improved Efficiency and Productivity

The efficiency of hydraulic systems contributes to improved overall productivity in construction projects. Construction equipment equipped with hydraulic engines can complete tasks more quickly and precisely, ultimately reducing project timelines and costs.

Remote Control and Automation

Advances in hydraulic technology have facilitated the development of remote-controlled and automated construction equipment. This not only enhances safety by reducing the need for human operators in hazardous environments but also improves overall efficiency.

Environmental Considerations

Hydraulic systems can contribute to environmentally friendly construction practices. Energy recovery systems and eco-friendly hydraulic fluids are examples of how hydraulic technology is evolving to address environmental concerns.

Cutting-Edge Construction Equipment

Excavators: Digging into Precision

Uncover the precision and power of excavators, evolved from humble beginnings to advanced machines, embodying the progress of the construction industry.

Cranes: Lifting Dreams to New Heights

Explore the heights cranes can reach, both literally and figuratively, as they lift heavy loads, symbolizing the elevation of construction capabilities.

Bulldozers: Paving the Way for Progress

Dive into the force behind land clearing and leveling – bulldozers – and how they paved the way for construction excellence, drawing inspiration from historical roots.

Technological Advancements

IoT Integration: Smart Machinery for Smart Construction

The integration of the Internet of Things (IoT) into machinery is transforming traditional equipment into smart, connected systems. This technological evolution is enhancing the capabilities, efficiency, and management of machinery across various industries, including construction. Here’s how machinery is becoming smarter through IoT integration:

Real-Time Monitoring and Data Collection

- Sensors: IoT-enabled sensors are integrated into machinery to collect real-time data on various parameters such as temperature, pressure, fuel consumption, and performance metrics.

- Continuous Monitoring: This data is continuously monitored, providing insights into the health and condition of the equipment.

Remote Diagnostics and Maintenance

- Predictive Maintenance: IoT enables predictive maintenance by analyzing equipment data to predict potential failures before they occur.

- Remote Diagnostics: Maintenance issues can be diagnosed remotely, allowing for quick and targeted interventions to prevent downtime.

Performance Optimization

- Data Analytics: Collected data is analyzed using advanced analytics tools, providing valuable insights into machinery performance.

- Optimization Recommendations: IoT platforms can suggest optimization strategies based on data analytics, enhancing overall efficiency.

Energy Efficiency

- Monitoring Energy Consumption: IoT sensors can monitor energy consumption patterns, identifying areas for improvement in energy efficiency.

- Smart Controls: Machinery can adjust its operations based on real-time energy demand, contributing to energy conservation.

Enhanced Safety Features

- Safety Sensors: IoT integration includes safety sensors that monitor environmental conditions and detect potential hazards.

- Automated Safety Protocols: Smart machinery can automatically implement safety protocols or send alerts to operators in case of unsafe conditions.

Supply Chain Integration

- Inventory Management: IoT enables machinery to be integrated into the broader supply chain, optimizing inventory management and facilitating seamless communication between equipment and supply systems.

Fleet Management

- Geolocation and Tracking: IoT-enabled machinery can be tracked in real-time using GPS technology, allowing for efficient fleet management and route optimization.

- Usage Analytics: Data on machinery usage and performance contributes to better decision-making for fleet management.

Human-Machine Interaction

- User Interfaces: Smart machinery often features intuitive user interfaces, making it easier for operators to monitor and control equipment.

- Automation: IoT integration allows for increased automation, reducing the manual workload on operators.

Integration with Cloud Platforms

- Cloud Connectivity: IoT-connected machinery often leverages cloud platforms for data storage, enabling accessibility and collaboration from anywhere with an internet connection.

- Scalability: Cloud integration provides scalability for managing large datasets and facilitates future updates and improvements.

Regulatory Compliance and Reporting

- Data Logging: IoT-enabled machinery can automatically log and report data required for regulatory compliance.

- Audit Trails: Smart systems provide detailed audit trails, aiding in compliance with industry regulations.

Robotics: Precision in Every Move

The role of robotics in construction machinery is increasingly becoming a transformative force, revolutionizing the way construction tasks are performed. Robotics in construction machinery involves the integration of automated systems and artificial intelligence (AI) to enhance efficiency, precision, and safety in various construction processes. Here are key aspects highlighting the role of robotics in construction machinery:

Automated Earthmoving and Excavation

- Autonomous Excavators: Robotic systems enable excavators to operate autonomously, performing tasks such as digging, trenching, and grading with precision.

- Efficiency: Automation reduces the need for human operators to perform repetitive and labor-intensive tasks, improving efficiency and lowering operational costs.

Drone Technology for Site Inspection

- Aerial Surveillance: Drones equipped with robotics technology are used for site inspections and monitoring.

- Data Collection: Drones capture high-resolution images and videos, providing real-time data for project managers and aiding in decision-making.

3D Printing Construction Robots

- Automated Construction: Construction robots with 3D printing capabilities can autonomously build structures layer by layer.

- Speed and Precision: This technology offers faster construction timelines and high precision in creating complex architectural designs.

Robotic Demolition

- Controlled Demolition: Robots equipped with demolition tools can perform controlled and precise demolition tasks.

- Safety: Robotic demolition minimizes human exposure to hazardous environments and reduces the risk of accidents.

Autonomous Vehicles and Equipment

- Automated Heavy Equipment: Construction machinery, such as bulldozers and loaders, can be equipped with robotics for autonomous operation.

- Collision Avoidance: Automated systems include sensors and AI algorithms to navigate construction sites, avoiding obstacles and ensuring safety.

Robotics in Concrete Placement

- Automated Concrete Pumping: Robotics is employed in concrete pumping systems, ensuring precise and efficient placement of concrete.

- High-Rise Construction: This technology is particularly useful in high-rise construction projects.

Remote-Controlled and Teleoperated Systems

- Teleoperation: Remote-controlled and teleoperated robotic systems allow operators to control machinery from a safe distance.

- Dangerous Environments: This technology is beneficial in hazardous environments, improving safety for operators.

Conclusion

As construction projects evolve, the machinery spotlight remains at the forefront, reflecting a rich history of innovation and technological advancement. From the early days of manual labor to today’s cutting-edge technology, witness the continuous revolution in the construction industry through the power of advanced machinery.